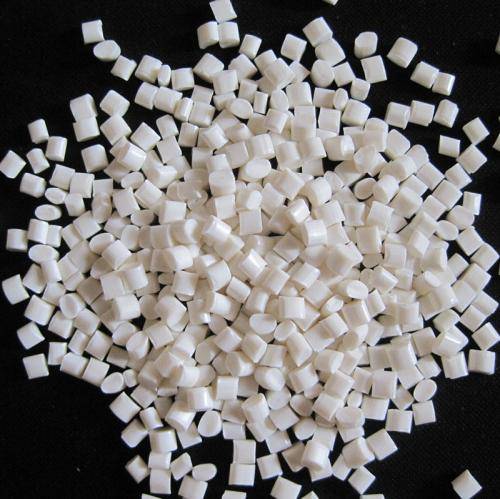

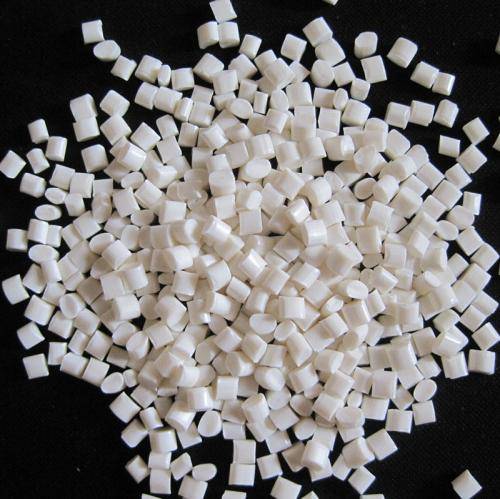

Acrylonitril Butadien Styren is a terpolymer in which polybutadiene is copolimerized with SAN. This results in a high-gloss material as well as good mechanical properties for use in technical products, such as cabinets for electronic devices, protective helmets, suitcases, pens, kitchen appliances and in toys such as the LEGO brick.

|

Hotline |

| +010 123456789 |

ABS – Acrylonitril Butadien Styren

Description

High flow grade ABS (Acrylonitrile Butadiene Styrene) raw material is a specially designed engineering plastic with higher fluidity, suitable for forming complex shapes and thin-walled components. Here are some key product introduction points for high flow grade ABS raw materials:

Material characteristics:

High fluidity: It has better fluidity and can be smoothly injected at lower temperatures, suitable for complex molds and thin-walled designs.

Excellent mechanical performance: maintaining good impact resistance and toughness, suitable for applications with high strength requirements.

Good surface gloss: After molding, the surface is smooth and has good aesthetics.

Processing performance:

Diverse molding processes: can be processed through various processes such as injection molding, extrusion, etc., suitable for rapid production.

Low temperature molding: Due to high fluidity, excellent fluidity and molding quality can be achieved at lower molding temperatures.

ABS resin

| Item | Unit | Test method | Test conditions | High flow stage |

| Model | ||||

| Melt Index | g/10 min | ASTM D-1238 | 200℃ × 10kg | 27 |

| Melt Index | g/10 min | ASTM D-1238 | 200℃ × 5kg | 3 |

| IZOD impact strength | kg-cm/cm | ASTM D-256 | 23 ℃,1/4",Notched | 27 |

| specific gravity | - | ASTM D-792 | 23℃/23℃ | 1.04 |

| Tensile strength | kg/cm² | ASTM D-638 | 23 ℃,50mm/min | 420 |

| Flexural strength | kg/cm² | ASTM D-790 | 23 ℃,15mm/min | 720 |

| Bending modulus | kg/cm² | ASTM D-790 | 23 ℃,15mm/min | 22000 |

| Rockwell hardness | R-scale | ASTM D-785 | 23 ℃ | R-105 |

| Sanitary softening point | ℃ | ASTM D-1525 | Annealed,50N,50℃/h | 93 |

| Heat deflection temperature | ℃ | ASTM D-648 | Annealed,1.8Mpa 1/4"thick,120℃/h | 93 |

| Heat deflection temperature | ℃ | ASTM D-648 | Unannealed,1.8Mpa 1/4" thick,120℃/h | 85 |

| Shrinkage | % | ASTM D-955 | 3.2mm | 0.4 ~ 0.7 |

| combustibility | UL-94 | File No. E162823 | HB 0.8 ~ 3 mm | |

Related products

-

1

1¥ 0.00Buy now

-

PA6 – Polyamide (Nylon 6)

Polyamide 6, also called Nylon 6, is a cool material with great tensile strength, elasticity and shine. PA6 is highly resistant to wear and chemicals such as acids and bases. But the material is also slightly hygroscopic, where the preoccupation with water acts as a softener, making the subject stronger and more cool. Pa6 without filler can, for example, be used in the manufacture of fibers, where the filled versions have a relatively high e-module that makes the material a strong candidate as a¥ 0.00Buy now

-

PA6.6 – Polyamide (Nylon 66)

Polyamide 6.6, also called Nylon 66, is a relatively rigid, hard, durable and thermal dimension stable material. Compared to PA6, PA6.6 has less water absorption rates, higher heat resistance and better insulating properties, making the material perfect for use in the textile industry as well as for technical articles in the automotive industry, among others.¥ 0.00Buy now

-

ABS – Acrylonitril Butadien Styren

Acrylonitril Butadien Styren is a terpolymer in which polybutadiene is copolimerized with SAN. This results in a high-gloss material as well as good mechanical properties for use in technical products, such as cabinets for electronic devices, protective helmets, suitcases, pens, kitchen appliances and in toys such as the LEGO brick.¥ 0.00Buy now

-

ABS – Acrylonitril Butadien Styren

Acrylonitril Butadien Styren is a terpolymer in which polybutadiene is copolimerized with SAN. This results in a high-gloss material as well as good mechanical properties for use in technical products, such as cabinets for electronic devices, protective helmets, suitcases, pens, kitchen appliances and in toys such as the LEGO brick.¥ 0.00Buy now